Hörtig Rohrpost at the Parisian Luxurious Warehouse

Key Facts

- Renovation of a long-time customer’s 20-year-old system

- Conveying cash from cashiers spread over the warehouse

- Implementation with minimal impact on running store operation

- Facing several constraints and cost minimization

Our customer

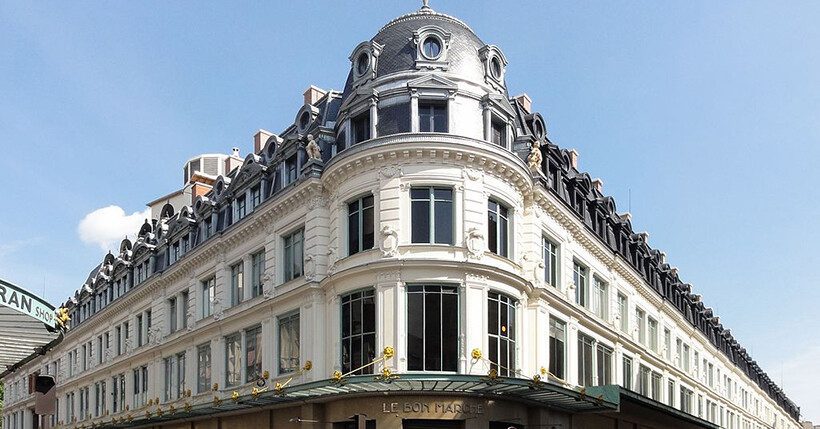

Le Bon Marché is a French noble warehouse that has a pioneer position for warehouses all over Europe. It is said, that it is the world’s first warehouse and for sure one of the most known.

Conveying money in the warehouse

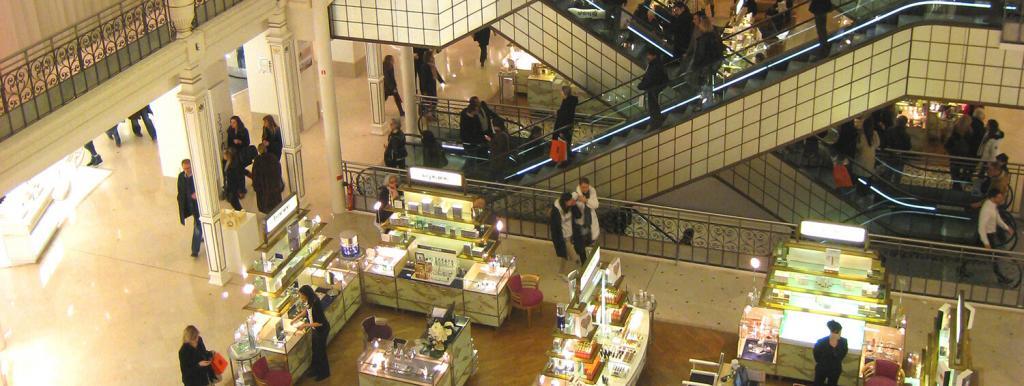

The warehouse has two buildings, that are separated by a street. Both are connected via a bridge that hovers above. The first building accommodates a huge grocery store as well as a department store. In the second building fashion brands are offered. In total, the two buildings have 15 cashiers spread over the floors.

The cash from these must be transported to a central place daily. Also, the supply with change must constantly be secured. To face this challenge efficiently, the warehouse has a pneumatic tube system installed for 20 years.

Long-time customer: Updating the system

Thus, the warehouse is one of our long-time customers and the pneumatic tube system is indeed still functioning, but certainly not up-to-date. In 2019 it was time for an update. This project was taken upon by our French distributor AMS.

Challenges of the project

1. Renovating during running operations of the stores

The system should be renovated with mini-mal impact on the warehouse operations.

To ensure, that the pneumatic tube system still works at all time, our distributor switched to the new one line by line. But only, after functionality tests have been completed successfully.

2. Very neat project timeframe

The project was scheduled very neatly into the time before the annual year-end sale. Thus, the timeframe of the implementation was very short. Furthermore, it was not desired to work during the opening hours of the stores.

Therefore, AMS had planned the implementation precisely in advance and put it into practice very time-efficient. The plant was fully prepared and modeled in the workshop beforehand. During the whole process, AMS held very close contact with the customer. In addition, the working hours of the technicians were accurately adjusted to the opening hours of the warehouse.

3. Reuse of the existing system

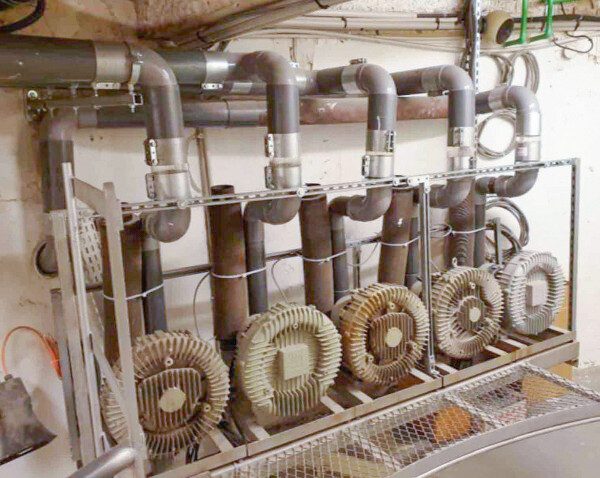

Because of the system being in use for many years, the sending history of the warehouse shouldn’t get lost. Also, all new transports should be tracked. With a diameter of 108×4, the system has a size that is not very common nowadays. It isn’t part of a standard pneumatic tube product range.

This challenge was met by producing the stations custom-made at the site in Bayreuth. Moreover, a PC that supervises all transports was installed at the warehouse.

4. Constraints due to registered building

During the renovation work, it had to be taken into concern, that the buildings are listed as a historic monument. Hence, no access to the tube lines, that are situated in the ceilings, could be provided.

AMS took this as a chance and reused the existing tubes and cables. Of course, only after they’d been inspected for reuse and necessary adaptions. This didn’t only lead to time- but also to cost-savings.

Bridging one road

The two mentioned warehouse buildings are connected by a covered bridge on the first floor.

To save room and hide the tubes from the customer, the lines are installed under the floor of the bridge. The cash arrives at the central cashier via the bridge in around 40 seconds.

Hörtig-System

In total, the system is around 1,500 m long. It contains 5 lines that function independently. To cross the street between the buildings, the tube lines run in the floor of the pedestrian bridge. The lines connect 15 stations of type 231. These were custom-made at the company site in Bayreuth because of the unusual diameter of 108×4. Le Bon Marché sends around 150 to 200 carriers filled with cash per day for 7 days a week. The carriers convey the cash with approximately 5 m/s. So it arrives at the central place in maximal 48 seconds.

The pneumatic tube system contributes to a smoothly flowing cash management at our customer’s for over 20 years. Thanks to the user-friendly operation the tellers can fully concentrate on customer contact. The full update in 2019 made sure, that it will stay that way in the future.

Customer’s pneumatic tube system

- 15 custom-made pneumatic tube stations with a diameter of 108×4

- 5 independent lines

- 1,500 tube lines

- Speed of the carriers ca. 5 m/s – The cash is at the central cashiers in 7 to 48 seconds

- One PC to supervise the operation of the pneumatic tube system

You can find the use case as a PDF under our references.

More information about sending cash

More News

- Hoertig Rohrpost presents itself at CHCC 2025 in Wuhan at Two Partner BoothsHörtig Rohrpost at CHCC 2025 in Wuhan: Innovative Hospital Logistics at Two Partner Booths Hörtig Rohrpost GmbH, a leading provider of modern pneumatic tube systems...

- Hörtig Rohrpost at Arab Health 2025 in DubaiThe Hörtig Rohrpost GmbH, a leading manufacturer of pneumatic tube systems, is participating in Arab Health in Dubai from January 27 to 30, 2025. This event...

- Hörtig Rohrpost GmbH at Medica 2024Hörtig Rohrpost GmbH at Medica 2024: Innovative Transport Solutions for Healthcare Hörtig Rohrpost GmbH will be present at Medica 2024 in Düsseldorf, the world’s leading trade...

- Hörtig pneumatic tube system on the Medical Mumbai expoHörtig Rohrpost presents innovative solutions at Medical Mumbai expo From February 16 to 18, 2024, the renowned technology trade fair Medical Mumbai expo was once again...