Is it important to you to be able to track the status and location of all shipments at all times? You want a system that optimizes your processes? Then you should pay special attention to the software behind your pneumatic tube system. Pneumatic tube software can give you control and traceability in shipments. It therefore not only increases transparency, but also allows you to optimize transport processes. The software can analyze material movements and predictively identify any wear points.

Version 4 of our RT-Win pneumatic tube software has a modular structure. Depending on customer requirements, the basic software can be supplemented with various apps. This is possible at any time. The Ethernet-based software offers interfaces to internal databases – for example, the laboratory information system. The central control logic is locally separated from the employees’ workstations. The software can be used by an unlimited number of PCs.

A selection of apps for RT-Win 4.0 pneumatic tube software

History

- Tracking and tracing of all current transports in real time

- List of all transports with time, sender and receiver information

- Detect anomalies in transports and clarify ambiguities

- Optimize system design and improve processes based on statistics

Predictive Maintenance

- Predicts possible sources of error based on various statistical and mechanical data

- Monitors the condition of the used pneumatic tube containers, the tube lines and the installed drives

- Initiates predefined actions in case of critical conditions

Information Screen

- Shows all incoming transports for a location

- Visually represents the status of transports (waiting, en route, delayed, arrived)

- Gives information about each transport, e.g.: Priority of shipment, timings, user and transport ID, sender, receiver.

Scan In/Out

- Tracking of materials transported in the pneumatic tube carrier

- Closed-loop tracking of materials such as medication and samples

- Digital real-time control of all steps of the transport process

- Cost reduction through reduction of “lost” materials

LIMS

- Customized connection of the pneumatic tube system to an SQL-based Laboratory Information Management System (LIMS)

- The LIMS automatically controls the shipments so that they are routed to the executing laboratory according to the desired sample analysis

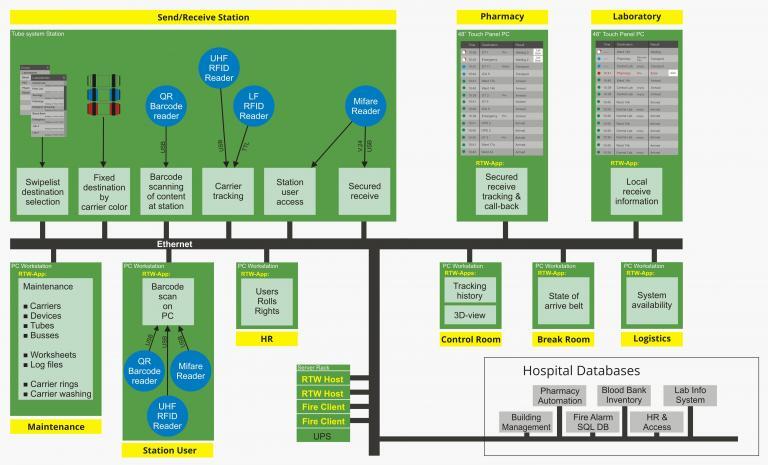

Exemplary integration of RT-Win 4 into the hospital infrastructure

The graphic shows how our pneumatic tube system could be integrated into a hospital’s infrastructure. The areas with a yellow background indicate in which hospital areas the respective app gives added value. All areas with a gray background depict databases to which the software could be connected.

You want a pneumatic tube system whose software thinks for itself?

Then do not hesitate to send us a non-binding inquiry. We will be happy to help you with any questions or concerns.

Download our pneumatic tube software RT-Win 4

You can download the latest version of our software here. Please note that you must first request a license from us in order to use it.