The system H61 uses ultra-modern technology to accommodate different requirements of in-house logistics. Various hospitals and companies use our H61 because it fits their needs perfectly. It is suitable wherever more complex logistics problems must be solved.

In contrast to our smaller 2-Point System H21, the system is computer controlled. This enables various additional features. We offer a range of smart additions in conjunction with our RFID-carriers – for instance the automated management of empty carriers or the priority sending of especially important goods.

The Smart System H61 can be used for up to 255 zones and 32.000 stations with diverters and passage methods. Our newly developed transfer method using a space-saving 16-fold turret enables significant shorter transport times than conventional transfer systems.

A variety of different stations can be mixed to match your needs. In the latest version, the stations are equipped with a 10″ touch screen as control and display panel.

Features of the system H61 standard equipment

- Menu-guided operation in different languages (Chinese, English, French, German, Thai)

- List of existing station numbers

- 1- to 16-digit selection

- Operation of all service functions with a portable programmer

- Remote control from each station or diverter

- Auto-setup function to parameterize central control

- Elimination of possible anomalies in the system through various algorithms of the software and through test routines

- Regular system operation after power outages with all carriers driving to their previously defined destinations

- Consistent ESD protection – CE-certified design

- Automatic checking of all integrated tube contacts to predict switch failures

- Error passive – failing components will not cause problems to other devices on the bus

- Tolerance of the control program against switch failures

- Automated carrier return via ID chip

- Storage 200 or more upcoming deliveries and cross-tabulations of the sending rate

- Shutdown of individual groups

- Control of traveling speed

- Control of the transport route

- Priority sending of important items

- Centronics printer interface (IEEE448), optically-coupled

- PC interface connectable at each device within the system

- Low energy needs concept means no additional power supplies and correspondent 230V-connection needed

- Standby power consumption only 24 W for 30 installed devices

- Transfer function for up to 255 additional lines, supported in all customary types of transfer designs (ring, star and network)

- Due to HÖRTIG multi-master bus: cable length up to 1500 m without additional power supply unit, supporting up to 120 stations and 120 diverters on each line

Station Design with 10” Touch Screen

Quick and efficient sending process

- Choose from personal Top 3 / Top 10 destinations

- Choose from station’s Top 3 / Top 10 destinations

- Grouped destination lists

- Quick dial (e.g. last receive, last sent)

- Send and receive history

Useful sending options

- Transport speed: slow, fast

- Priority: norm, fast, now

Adaptable to individual needs

- Fully configurable: e.g. layout, colours, names and display of specific elements

- Multi language, including Arabic, Cantonese, Thai etc. – any user language integrable

- Many optional features: e.g. display of video, audio and messages

About the 10” display

- Resolution: 1024 × 600 pixel

- 10” big, easy to read display

- Intuitive interface

- High quality surface file for long-term use

For more information, please get in contact!

Station types for the smart Universalsystem H61

For the pneumatic tube system H61, you can choose between the following stations:

- 1-fold, 2-fold, or 3-fold sending station (dispatch from below)

- Top-loader

- Front-loader 1- or 2-fold

- Table-station with fully automated carrier dispatch

- Endstation with receipt and dispatch from below

- Automatic-endstation

- Sending and passage Station

- Beginning, passage and endstation

- Laboratory station with smooth reception bow or conveyor belt

The stations are offered in different diameters. Contact us for further information and product data sheets!

Selection of our pneumatic tube stations for our system H61

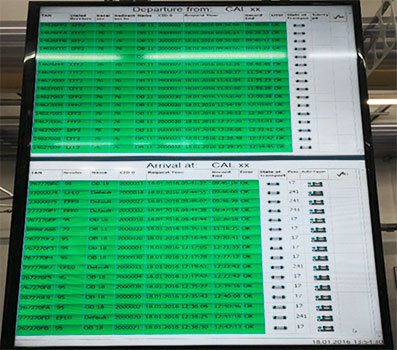

Arrival & Departure Screen: Overview of all transports

The H61 can be optionally equipped with Arrival and/or Departure Screens. On the screens, your employees immediately see detailed information about the transport after entering a carrier:

- Time of carrier entry

- Input station

- Contents of the transport

- Departure time

- Arrival time

This allows staff to keep track of all open, ongoing and completed transports directly from their workplace at any time.

Huge Arrival & Departure Screens that are installed centrally in a laboratory

Small touch panel besides the station