Das System H61 ist, im Gegensatz zum kleineren Punkt-zu-Punkt System H21, computergesteuert und bietet dadurch zahlreiche Vorteile. Es ist für bis zu 255 Zonen und 32.000 Stationen mit Abzweigungen angelegt und kann modular erweitert werden. Die Vielzahl an unterschiedlichen Stationsformen sind in der neuesten Version mit einem 10” Touchscreen als Bedien- und Anzeigefeld ausgestattet.

An der Sendestation wird die jeweils gewünschte Zielstation angewählt und der Transportbehälter fährt automatisch ab. Bei RFID-Behältern entfällt die Zielwahl. Unser platzsparender 16-facher Transferrevolver ermöglicht wesentlich kürzere Transportzeiten als herkömmliche Überleitsysteme. Mit Multicarry-fähigen Stationen fahren Behälter alle zehn Sekunden ab. Einen praktischen Überblick über alle Transporte geben Arrive & Departure Screens.

Das H61 bietet in Kombination mit dem Einsatz von RFID-Behältern und Transferrevolvern eine Reihe von smarten Features – beispielsweise das automatische Management von Leerbehältern oder die Priorisierung von Sendungen. Das System kann außerdem über eine Datenschnittstelle in Informationssysteme des Kunden (z. B. LIMS, BIMS, HIMS) integriert werden.

Serienmäßig vorhandene Features des Systems H61

- Menügesteuerte Funktionen mit wählbarer Bediensprache (D, GB, F, RC, Thai)

- Stationsnummernverzeichnis

- 1-16 stellige Zielwahl

- Bedienbarkeit aller Ein- und Ausgabefunktionen über tragbares Hand-Programmiergerät

- Fernbedienung der Zentrale und aller Systemkomponenten von jeder Station oder Weiche aus

- Umfangreiche Auto-Setup-Funktionen zur Parametrierung der Zentrale

- Beseitigung von eventuellen Unregelmäßigkeiten im System durch diverse Algorithmen der Software und Testroutinen

- Regulärer Systembetrieb nach Stromausfall mit Ausfahrt eines liegengebliebenen Transportbehälters an der vorher bestimmten Zielstation. Alle in den Stationsspeichern stehenden Transportbehälter fahren zu dem vor dem Stromausfall bestimmten Ziel.

- Stabilität gegen statische Aufladung durch EMV-konformes Konzept

- Selbstkontrolle der im System integrierten Fahrrohrkontakte zur Vorhersage von Schalterausfällen

- Toleranz des Fahrprogramms gegen Rohrschalter-Ausfälle

- Automatischer Rücktransport des Behälters via ID-Chip

- Grundmodul für Speicherung der letzten 200 Sendungen und Kreuztabelle der Sendefrequenz

- Abschaltung einzelner Gruppen

- Steuerung der Fahrtgeschwindigkeit

- Fahrwegkontrolle

- Prioritätsschaltung

- Druckerschnittstelle – Centronics, optisch entkoppelt

- PC-Interface an jeder Stelle der Anlage anschließbar

- Keine Zusatz-Netzteile und entsprechende 230V-Anschlüsse durch gezieltes Low-Power Konzept

- Standby-Leistungsaufnahme bei 30 installierten Geräten nur ca. 24 W

- Überleitfunktion für bis zu 255 weitere Linien mit Unterstützung aller marktüblichen Überleittypologien, wie Stern-, Ring- oder BUS-Anordnung der Einzellinien

- Durch HÖRTIG-Multimaster-BUS Kabellängen bis zu 1500 m ohne Zusatz-Netzgerät, bis zu 120 Stationen und 120 Weichen je Linie

Stationsdesign mit 10” Touchscreen

Schneller und effizienter Sendungsprozess

- Auswahl aus persönlichen Top 3 / Top 10 Ziele

- Auswahl aus den Top 3 / Top 10 Zielen der Station

- Ziele zu sinnvollen Gruppen zusammengefasst

- Schnellauswahl (z.B. letztes Ziel)

- Sende- und Empfangsverlauf

Praktische Sendungsoptionen

- Transportgeschwindigkeit: langsam, schnell

- Priorität: norm, schnell, jetzt

Anpassbar an individuelle Bedürfnisse

- Konfigurierbar: z.B. Layout, Farben, Namen, Ausblenden bestimmter Elemente

- Verschiedene Sprachen, inklusive Arabisch, Kantonesisch, Thailändisch etc. – jegliche Sprache integrierbar

- Viele optionale Features: z.B. Anzeige von Videos, Audio und Nachrichten

Über den 10” Display

- Auflösung: 1024 × 600 pixel

- 10” großer, gut lesbarer Display

- Intuitives Interface

- Hoch qualitative Oberfläche

Für mehr Informationen nehmen Sie bitte Kontakt mit uns auf.

Stationsformen für das Universalsystem H61

Für das Universalsystem H61 können Sie aus folgenden Stationen wählen:

- 1-fach, 2-fach, oder 3-fach Sendestation von unten

- Top-Lade-Station

- Tischeinbaustation mit vollautomatischer Abfahrt des Behälters

- Endstation mit Senden und Empfangen von unten

- Automatik-Endstation

- Anfangs- und Durchlaufstation

- Anfangs-, Zwischen- und Endstation

- Laborstationen mit Auslaufbogen oder Förderband

- Frontlade-Station

Die Stationen werden in verschiedenen Durchmessern angeboten. Kontaktieren Sie uns für weiter Informationen und Produktdatenblätter!

Auswahl unserer Rohrpoststationen für das H61

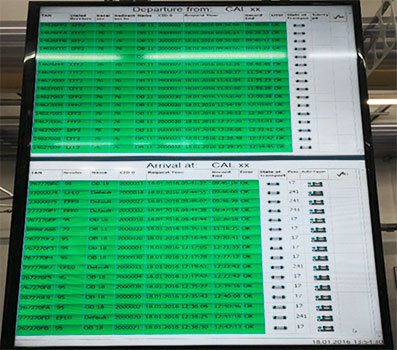

Der Arrive & Departure Screen: Überblick über alle Sendungen

Das H61 kann optional mit Arrive und/oder Departure Screens ausgestattet werden. Auf den Bildschirmen sehen Ihre Mitarbeiter nach Eingabe eines Behälters sofort detaillierte Informationen über den Transport:

- Zeitpunkt der Behältereingabe

- Eingabestation

- Inhalt des Rohrpostbehälters

- Zeitpunkt der Behälterabfahrt

- Ankunftszeit

Ihre Mitarbeiter behalten damit direkt am Arbeitsplatz jederzeit den Überblick über alle offenen, laufenden und beendeten Transporte.

Große Ankunfts- und Abfahrtsscreens zentral in einem Labor installiert